Simplify the installation process by exploring this helpful guide on how to cut stacked stone veneers, the different stone types, and the tools required.

Defining Veneers

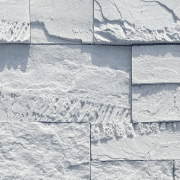

Before understanding the best techniques to cut stack stone veneer, it’s important to understand how stacked stone varies from other types of stone veneers. There are two primary types of stone veneers known as masonry veneers and modular veneers. Masonry veneers include ledgestone and fieldstone, which require professional installation.

Modular stone veneers, such as stacked stone veneers, are referred to as “modular” because the shape and style of the panels can be customized for easy installation. After determining stacked stone veneers as the best stone type for your project, the next step is to understand how to cut it for proper application.

The Required Tools

The best method for cutting stacked stone veneers requires using a wet saw and an angle grinder. These tools work in tandem to effectively cut and shape the stack stone veneer panels.

The tile wet saw is designed to cut through stone and tile and the angle grinder to accomplish more precise and unique cuts. Before learning how to cut stacked stone veneers, it’s best to understand what kind of tools being used to complete the job.

The Tile Wet Saw

A tile wet saw operates using a rim diamond blade and serves as the primary cutting tool for installing stacked stone veneer panels. A tile wet saw works by utilizing water as a lubricant when using the blade to cut through stone.

The water recycles through a closed loop system to drain the water from the stone and into a small pump to cycle it back through the blade. It’s important to continuously refresh the water in a tile wet saw during the cutting process to routinely clean off sediment and maintain the water lubrication.

The Angle Grinder

An angle grinder is a hand-held tool that’s used to cut, polish, and finish a variety of materials. The angle grinder takes care of the remaining customizations needed for cutting stacked stone veneers. After utilizing the tile wet saw to cut stacked stone into panels, it’s likely you’ll require an angle grinder to help perfect the job.

Whether you’re cutting a panel to support a curved pipe or a rectangular panel to frame a light switch, using an angle grinder is a must. Using an angle grinder doesn’t require a lubricant, which means it requires a higher level of manual labor than a tile wet saw when cutting stacked stone veneer. The blades on the angle grinder also require frequent replacements to ensure high-quality cutting.

The Cutting Process

The type of process required to cut stack stone veneer can depend on the type of wet saw model you’re using. Explore the following outline to learn about the basic functioning of using a wet saw and angle grinder for cutting stacked stone veneers.

Using a tile wet saw requires the following steps:

- Prep the saw by positioning it on an even surface and ensure there’s enough space for the tool to spray water. Be mindful of positioning the wet saw at a level that’s comfortable for your height.

- Mark the place of your desired cut and adjust the blade until the wet saw aligns with the mark by squeezing and dragging the fence into position.

- Prepare to use the wet saw by placing the widest part of the stacked stone veneer panel between the fence and blade. Press the guard over the wet saw blade and turn on the tool.

- Allow the wet saw to reach maximum speed and check for adequate water flow before proceeding. Use both hands to gradually feed the stone into the blade of the wet saw. Do not force the saw to go faster than required to avoid the risk of fracturing, chipping, or breaking the stone.

- After completing the intended cut, immediately power off the wet saw and allow it to come to a complete stop before proceeding to use the angle grinder.

Using an angle grinder requires the following steps:

- Prepare the angle grinder by ensuring the disc is properly attached and bolted.

- Align the disc of the angle grinder up to the desired point to cut the stacked stone veneer.

- Avoid forcing the disc into the material to cut and angle the grinder so that the sparks move in the opposite direction of you.

- Allow the angle grinder to reach maximum speed and gently press it onto the stone being customized. Proceed to cut through the stone while keeping the angle grinder at 90 degrees to avoid bending the tool. Do not stop the tool mid-cut to avoid the disk becoming stuck in the stone.

Purchasing Tools

Before gearing up to operate, it’s important to ensure that you’re purchasing high-quality tools that are within your price range. Tile wet saws are available to rent from local hardware rental locations. It’s best to rent a higher-quality tile wet saw for a temporary project than to invest in a lower-quality one that affects the results. High-quality angle grinders are easier to come by within a reasonable price range and have a renting option.

Safety Practices

Utilizing the right tools for cutting stacked stone veneer means you must learn the safety procedures for handling them. If you’re conducting a DIY project, it’s especially important to recognize safe practices to avoid compromising your safety and the quality of your stacked stone project.

It’s vital to wear eye and ear protection and consult the instruction manual before using these tools for cutting stacked stone. In addition, it’s best to wear gloves when operating both tools to protect your hands from stone fragments and the impact of the blade itself.

Our helpful guide on how to cut stacked stone veneer is just one of the various services we offer here at RockSolid Veneers. We are your hub for high-quality stone veneers manufactured in a variety of styles and color schemes to suit the building project of your dreams.

If you’re seeking additional tips on your installation process, feel free to reach out to our expert staff for assistance. If you need to figure out a starting point for your next stone veneer project, we welcome you to use our site to get a free quote today!