The lightweight density of manufactured stone also permits an easier installation process, like stucco, and eliminates the need for additional foundations, wall ties, lintels, or ledges. Manufactured stone also doesn’t require professional assistance because the process does not go beyond a do-it-yourself application. There’s a broad range of manufactured stone types, but the benefits remain the same across the board. Read on to learn how to use different types of manufactured stone for various applications and how their features make them different from one another.

Basics of Manufactured Stone

Manufactured stone offers a variety of options for homeowners looking to improve the exterior or interior of their property. The reasonable cost of manufactured stone has increased its popularity on the market for home improvements. The broad range of faux stone types can also complicate the decision-making process. The varying shapes of manufactured stone provide an easy starting point for deciding which type of manufactured stone will suit your project.

The type of installation process required depends on the type of manufactured stone you’re using. The size and scope of the project are best ruled out prior to installation to avoid an uneven application. The following steps illustrate the general steps for installing different types of manufactured stone veneer:

- Install sheets of expanded metal lath as a foundation for mortar underneath (if the application requires mortar between the joints).

- Cover the entire metal lath with a scratch coat to ensure the surface adheres to stone veneer.

- Lay the stones out into sections to plan the application layout and perform trimming to reshape the stones if necessary.

- Prepare the mortar mix for bonding the stone veneer to a workable consistency. Use a trowel to spread the mortar onto the scratch coat of each stone veneer.

- Begin applying the stone veneer pieces at the corners of the wall. It’s best to begin installing stone veneer pieces from the bottom and working upward to ensure uniformity.

- Grout the joints of the stone veneer pieces by filling a grout bag with mortar and squeezing it along the stone joints to cover the trimmed edges with mortar. Complete the installation by applying a seal to the veneer stone per the manufacturer’s instructions.

Shapes of Manufactured Stone

Before exploring how to use different types of manufactured stone, it’s important to learn about the three main popular types based on the stone’s shape, including field stone, river rock, and ledgestone.

Fieldstone

The fieldstone type consists of gathered material and aggregates from authentic stone left in its natural state. Fieldstone veneers are random-size stones that have an intentional appearance of being uneven and stacked. The irregular shapes of fieldstone help showcase a rustic appearance. The best application for fieldstone includes interior fireplaces, home facades, and landscaping.

River Rock

The river rock type consists of smooth, oblong river rocks or cobblestones that come in a variety of sizes, colors, and textures. Using river rock can help illustrate depth in the architecture of a home. The best application for river rock includes rough borders, pond and stream beds, or general wall construction. River rock suits projects where you want a uniform appearance in size, depth, and surface texture.

Ledgestone

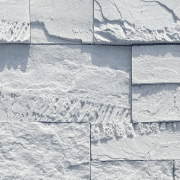

The ledgestone type consists of fragmented and symmetrical stones that come in a variety of sizes, colors, and textures. These manufactured stones become stacked together using cement, mortar, and sand mixture. Ledgestone veneers are typically short, wide, and have flat-cut sides. The front of a ledgestone veneer has a jagged texture for a rustic appearance that resembles natural stone. The best application for ledgestone includes residential home facades, interior fireplaces, and landscaping wall applications.

Styles of Manufactured Stone

Explore the following style descriptions to learn how to use different types of manufactured stone based on the core features that suit the personalized style of your interior or exterior application.

Southern Ledgestone

The southern ledgestone veneer provides an informal and rugged appearance that suits a broad range of home applications. Southern ledgestone also gives the option of being stacked or applied by using mortar in the joints.

Hackett Stone Veneer

Hackett stone veneer, also known as castle rock, offers a European accent to the appearance of a home. Hackett stone resembles the old-world aesthetic of castle rocks that come in a variety of colors and textures for a customizable application. Hackett stone veneer suits a uniform appearance using rectangular- or square-shaped stones. Hackett stone has a thinner consistency and lighter density than other styles of manufactured stone. For this reason, Hackett stone has thinner joints between stones. The weathered style of Hackett stone makes applying the stone veneer with mortar joint beneficial to accentuate the old-world appearance.

Dry Stack Stone

The dry stack stone veneer suits both contemporary and traditional stylistic preferences. Stack stone comes in a variety of styles, colors, and textures for a broad range of applications and provides a seamless finish. Stack stone typically has a loose format with a flattened cut to lay flat against the wall. The rough-cut shapes and sizes of stack stone provide the option of a loose format and dry stack patterns. The dry stack stone technique has less space between the stones than other stone veneer applications and places focus on the surface of the stone itself.

RockSolid Veneers is your hub for high-quality stone veneers manufactured in a variety of styles and color schemes to suit the building project of your dreams. If you’re seeking additional tips on your installation process, feel free to reach out to our expert staff for assistance. If you need to figure out a starting point for your next stone veneer project, we welcome you to use our site to get a free quote today!